Archi-Union uses "cyborg fabrication" to build Venue B conference centre in 100 days

November 23, 2018Archi-Union Architects has completed a conference centre on Shanghai's West Bund in just 100 days, using robot-assisted design and construction.

Called Venue B, the centre was built to host conferences centred around artificial intelligence (AI). Because of this, Archi-Union felt it was appropriate to use innovative digital construction techniques in the building's creation.

This follows the ethos of the Shanghai-based firm, who previously worked with robots to the build the complex brick structure of the Chi She gallery, and has also completed numerous other buildings with complex geometries.

Venue B features some of the most lightweight structures available in modern buildings, thanks to the combination of algorithms used in the planning stages and prefabricated construction methods.

"AI has been rapidly refreshing our perceptions about the world," said the team, explaining that they set themselves the challenge: "How can we present an urban public exhibition space, which carries the essence of AI technology in 100 days?"

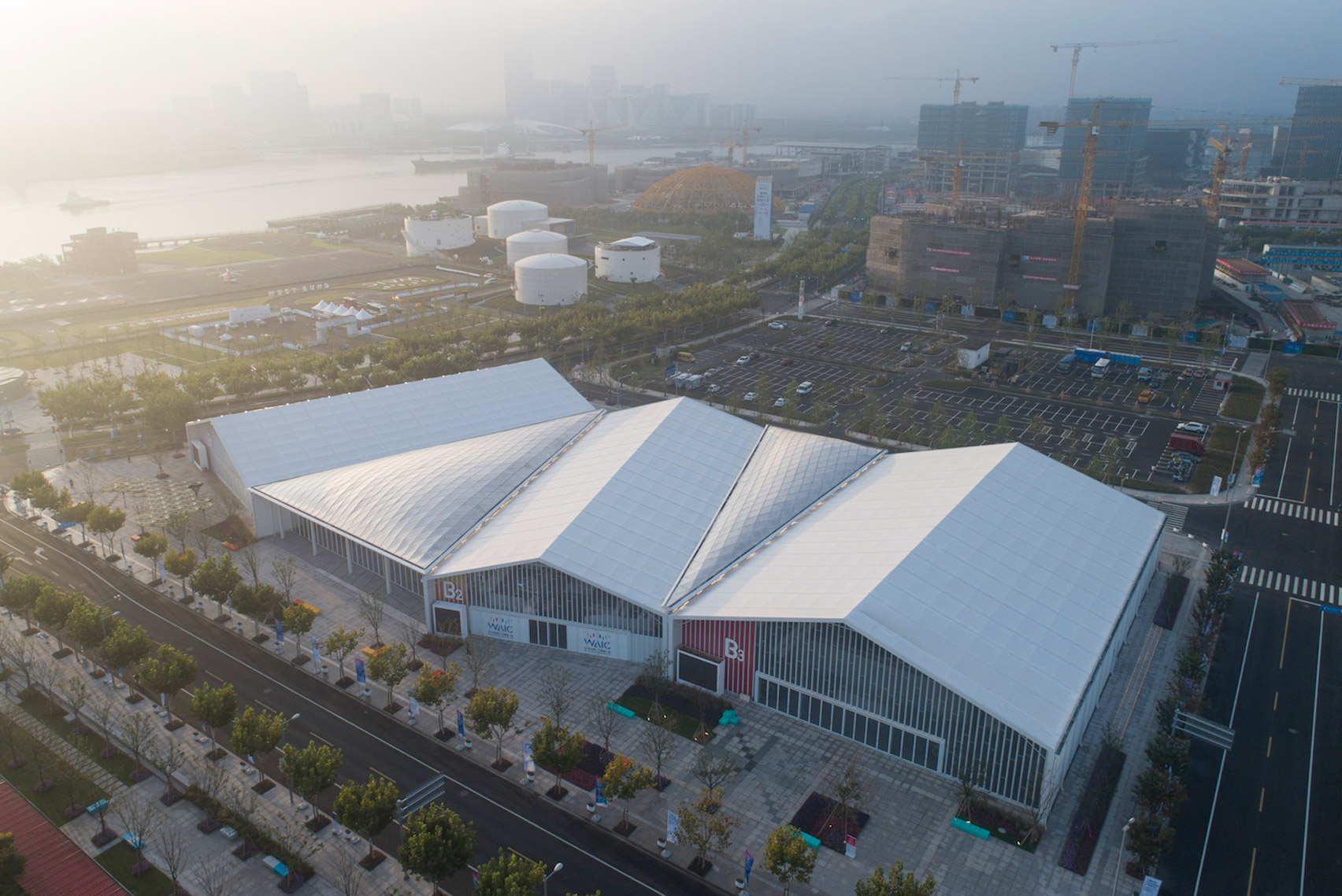

The complex consists of three conference venues that sit at slightly rotated angles to each other. These angles create two triangular spaces in between the halls, which contain garden courtyards.

The buildings are white, to blend with the overall language of the West Bund's existing public buildings, which are all pale in colour and modernist in form.

Facades that face the street are as closed as possible to avoid disturbance during summits, but those that face the internal gardens are open in order to allow natural light and air to flow through the spaces.

In the larger of the central triangular courtyards is a shared garden, constructed in wood to soften the space and encourage relaxation. This garden serves as a rest station between summits. A thin vaulted roof, also made from wood, provides shelter for the garden space.

"Both courtyards are covered with a digital prefabricated timber vaulted roof, in which the larger one has a span of 40 metres and its structural thickness is only about 0.5 metres," said the architects. "It is the most economical inter-supported steel-wood roof in the world."

This garden also houses the world's largest 3D-printed coffee pavilion, which takes the form of five translucent arches, with a coffee bar as well as tables and chairs – all constructed in the same manner as the pavilion itself. The use of 3D-printing has made the process of building and fitting the space very rapid.

"The entire process from design to construction of the coffee pavilion celebrates the cooperation of man-machine intelligence," said Archi-Union.

"In total, digital design and fabrication technologies have helped to achieve 200 square metres of printed building areas, 40 printed chairs and 12 tables within 25 days."

Venue B's main structure uses a prefabricated light aluminium truss system, which has the lightest unit weight of all known materials. Both the roof structures over the three conference halls and the garden spaces are also exceptionally lightweight.

The architects were able to achieve the material lightness of Venue B's roof by using algorithms that calculated the best angle of the vaulted structures to ensure that the force was distributed evenly. The arching roof is balanced by the steel trusses and reinforced at the corners.

The joints in the roof are formed of hollow aluminium structures that further reduce its weight. The ceiling is slightly raised above the main conference space in order to allow ventilation.

The installation of the prefabricated components according to a digital plan vastly improves the efficiency on site and requires fewer labourers than traditional construction. For this reason, on-site construction of the 2,000 square metre timber shell took only 29 days.

A minimum amount of materials were used for the structure, making the building more sustainable and reducing the cost of the build.

Outside Venue B is a black and white 3D-printed pavilion designed and constructed by a team from the University of Stuttgart's Institute for Computational Design (ICD) and the Institute of Building Structures and Structural Design (ITKE).

Named the Elytra Filament Pavilion, the structure was first revealed outside the V&A museum during London Design Festival 2016. A 3D-printing arm slowly added to the woven structure of the pavilion throughout the course of the festival.

The canopy is made up of 40 hexagonal cells, each made of black carbon fibre and transparent glass fibres woven together. Just as with the conference centre itself, the pavilion is exceptionally lightweight.

Archi-Union Architects, founded in 2003 by Philip Yuan, examines how to encourage cooperation between man and machine in the building process.

Yuan explores how robotics can improve architecture in terms of the speed of build, and how it can be used to create ultra-precise geometries that are not currently possible for buildings designed by man alone.

Venue B, which was completed in time for the World Artificial Intelligence Conference in September 2018, sits in the city's once-industrial West Bund area.

The West Bund now has more than 20 cultural and art buildings along a 8.4-kilometre stretch of the river, including the Long Museum, Tank Shanghai and the David Chipperfield-designed West Bund Art Museum with its Centre Georges-Pompidou & West Bund cooperation programme.

The area also has a new central business area focused on innovative and creative industries.

Photography is by Fangfang Tian.

The post Archi-Union uses "cyborg fabrication" to build Venue B conference centre in 100 days appeared first on Dezeen.

from Dezeen https://ift.tt/2BrSnfC

via IFTTT

0 comments